Tires

The single most important part of the whole suspension system is THE TIRE. Tires are absolutely, positively, hey-Joe-no-foolin THE most dominant part of the suspension. Being on the right tire for the job at hand will buy you more time than any single other suspension improvement, and in terms of autocrossing (and road racing, to a point) tires buy you more time than anything outside of more seat time - PERIOD.

So half, maybe even 3/4 of the battle is getting on the right tires. If you have the right tires and everybody else is on the wrong tires, you win.

If there are multiple tires eligible for your class, then it sucks to be you, because you're going to have to test and try them all - because being caught on the wrong tires means you lose. And when the tires change throughout the season - as they most certainly do; no race tire stays the same between build codes because the manufacturers are in a constant scramble to stay ahead of the other guy - then it really sucks to be you if you are behind the curve. Tire. Wars. Suck.

In any case, the first step to building a winning car is to determine the tire you will be using; all else falls out of that.

Picking the winning tire is part luck, but mostly testing. Buy as many different sets of tires as you can afford, and then test them, back-to-back, in the same conditions. Try and get a handle on what makes the tire work, particularly in terms of temperatures and pressures. The trend has been towards tires that start working at lower temperatures (and go off at lower temps as well; the tire will overheat and get "greasy") but there is no promise that this trend will hold and you cannot make any assumptions about anything. Particularly, this year's wonder tire can easily become next year's dogshit (see BFG G-Force and Hoosier A3S04 (dogshit), vice BFG R1 and Hoosier A3S03 (wonder tire)

The tire manufacturers change their tires constantly. Sometimes it is due to regulatory pressure (like when the A3S03 was forced to abandon the Kevlar belts for steel belts in the A3S04) but most of the time is is the constant race to be faster than the other guy. You cannot assume tires will be the same from year to year, or even build code to build code.

If you cannot afford to test, the next best thing is to keep an eye on the guys with money and watch what they do. They can afford to test, and they are doing so. If they suddenly get faster, that's probably tire at work and you should try and beg, borrow, or steal a run on the same tires to see what they feel like.

Normally, the difference between a good tire and a better tire is immediately obvious to the driver; you won't need many tries to figure out what tire you need to be on. (My first time on Hoosiers - old, slightly worn-out Hoosiers at that - compared to the Kumho V700s I had been running was night and day. It took exactly two corners to see just how much better the tire was)

Note too that there's more to a tire than just raw grip. There is transitional response (how fast the tire will cut from full left to full right), recovery time (how fast the tire regrips once you cross the line and start it sliding) temperature sensitivity, and grip itself can be broken up into lateral and longitudinal grip. Different cars will respond differently to different aspects of the tire's performance envelope, and what might work on one car might not work on another.

For example, a tire that trades a little lateral grip and transitional response for forward bite will tend to work better on a high powered rear wheel drive car (that typically has a hard time putting all its power to the ground) than on an underpowered front wheel drive car that cannot power the tires loose when parked on an ice floe. The only way to know is to test, test, test, and pay attention to what is going on around you.

Once you have the tire, there is a particular performance envelope that it needs to be kept in to maximize its performance. There is a particular camber angle, pressure, slip angle, temperature, age, loading yadda yadda that puts the tire in its Happy Place where it provides the most grip, stability, response, etc.

This is important - if everybody is on the same tires, he who keeps his tires in their Happy Place the largest percentage of the run time, wins. When you have an advantage in WHICH tire you are on, you can get away with being sloppy here and still win (assuming a large enough delta between "right tire" and "wrong tire") But once you are all on a level playing field, tire-wise, the difference between the champ and the also-ran is in the execution of keeping that tire happy.

Any given tire, once in its happy place, produces a certain maximum amount of grip. That max amount of grip has an enormous amount of influence on suspension tuning. There are things you can get away with on a low-grip street tire that will just ruin your day on a high-grip race tire - and the higher the grip, the more true this becomes. High grip == more force, and the suspension needs to be able to deal with it.

Certain tires are more finicky about their happy place than others. Tire A may work well from 50 deg F to 250 deg F. Tire B may be a rock from 50-120 deg F and a greaseball from 180 deg F on up. Tire A may lose 20% of its grip at camber angles +/- 1 degree from optimal, where tire B may only change 3% over a 5 degree camber range. Oh, and it may be surface dependent too. A big part of the battle is to figure out exactly where your tires are sensitive/insensitive and control the parts that make the biggest difference.

...and those parameters need not be STATIC either. A given tire may not care what the camber angle is within 5 degrees, but it may not tolerate CHANGES in camber angle faster than 1 deg/sec. Etc etc etc.

So then, we want to find the best tire we can, and we want to keep it happy, and we have a ton of testing to do in order to discover exactly where the Happy Place is, and how sensitive the tire is to changes.

Wider is almost always better. It is usually worth doing whatever you have to do to get a wider tire under the car, even if it means a larger tire diameter. Every single time we put a wider tire under the car (even if it was taller) we went faster.

For my opinions on "street tires", see this article. In a nutshell, I think they are a viable option for people looking to play at a local/regional level. At a National level though, they don't get you out of the tire testing game, the number of tire brands/models that need testing is actually LARGER than the number of R compounds normally available, and the tires themselves are usually just as expensive as the R compounds. The extra wear you get out of the (notionally) harder compound is a false economy, if you are really set on winning.

Until the day when the SCCA comes up with a spec tire class, a large portion of the efforts of a winning team will be spent on tire testing, and that is independent of if the tire is a "race tire" or a "street tire" - because the rewards of being on the "right tire" (and the penalty associated with being on the "wrong tire") are so large. If you aren't testing, you're losing - or you're getting lucky, because everybody else in your class is lazy too.

Tire Theory

Now let's talk about how tires work.

Tires provide grip through a combination of mechanical interlock with irregularities in the road surface (think meshing gears), and through molecular adhesion between the rubber in the tire and the road itself (think glue). Race tires, being both soft and sticky, have higher levels of both interlock and adhesion than a firm and dry street tire.

The downside of course is that race tires wear out much faster than harder tires, but for racing purposes, that's really not a big deal.

The harder the tire is pressed into the road surface, the more grip it provides. With the extra normal force pressing down on the tire, the rubber in the tire is pressed deeper into the road surface and so fills in more and more irregularities, providing more and stronger mechanical interlocks, and more contact area with which to provide molecular adhesion.

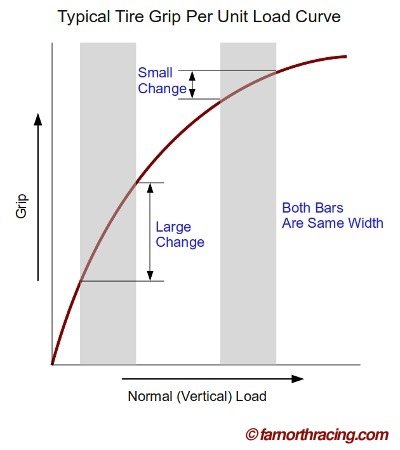

The key to this process though is that while more force pressing the tire into the road provides more grip, the amount of grip generated per added unit of normal force declines on a curve. For example, 100 lbs of normal force (which I'll call load from now on) might provide 100 lbs of grip, 200 lbs of load might provide 150 lbs of grip, and 300 lbs of load might provide 175 lbs of grip. Always more grip with more load, but also always less grip per unit load as grip increases.

This property means that for any pair of tires, they will provide maximum grip when equally loaded.

You can see that using our example tire from earlier: Load both tires with 200 lbs of load each, and you get 2 x 150 lbs = 300 lbs of grip. But move 100 lbs of load from one tire to another - still 400 lbs total load - and you get 100 + 175 = 275 lbs of grip, or 25 lbs less grip than with both tires equally loaded.

This has important implications when we start talking about static weight distribution and dynamic weight transfer.

But more than that, it has implications for tires as a single unit, because a similar mechanism exists for the tire as a whole. A 10" wide tire can be treated (from a grip perspective) as 10 x 1" wide tires placed side by each (or even 100 x 0.1" tires, and so on, until the width of our theoretical tires reaches the scale of an individual rubber molecule and the analogy becomes ridiculous) In order to get maximum grip out of our 10" wide tire, each of those "subtires" must be equally loaded. Any bias of load towards one side of the tire or the other is going to create more grip out of the more heavily loaded side, but less grip on the more lightly loaded side. And because you always lose grip faster than you gain, the bias in load means a net loss in grip.

Because we transfer load to the contact patch through the tire sidewalls and the air stored inside the tire, there is going to be a specific camber angle and air pressure at which the tire produces maximum grip. And because the tire is springy, and a large determinant of the tire spring rate is the air pressure, the camber angle that produces max grip for a given air pressure will most likely be different than the max grip camber angle at a different air pressure.

And that's not counting the Weird Harolds that can sneak in based on tire construction. The original BFG R1 circa 1998 was designed with inner sidewalls stiffer than the outer sidewalls, specifically to address Stock-class cars that could not dial in much in the way of negative camber. By softening the outside sidewalls, more load was carried on the inside of the tire (notwithstanding the camber-challenged car trying to load the outside sidewall more heavily) with the result that the tire was more equally loaded across the contact patch, producing more grip than it would with sidewalls of equal stiffness.

So then, a big part of keeping a tire in its happy place is finding the camber angle and pressure combination that produces maximum grip, and then keeping it there (as best you can) throughout the entire range of motion of the suspension.

We will never achieve this with a production-car-based suspension. Some can come close (C5 Corvette) but most cars, especially MacPhearson Strut cars... no way, no how. So the job instead becomes to keep the tire as happy as we can, given the constraints forced on us by the suspension.

A legitimate solution to the problem is to use a tire constructed to be camber-insensitive; typically a low-pressure, soft-sidewall tire that relies more on air pressure to transmit load than stiff sidewalls. Sadly, those tires are often unavailable to us (because of rules) and sometimes what you gain in max grip you lose in transient response.

I discuss tire pressures in a more practical sense in a later chapter.

This is one of the major reasons you need to model your suspension. You need to know how camber changes in roll for your car, and you need to see how those curves change at different ride heights. If you have control over your suspension design, you might be able to influence those curves by changing A-arm lengths or chassis pickup points, but if you can't, there is probably an ideal ride height where camber change in roll is minimized.

Don't think, either, that you can get the tire companies to cough up this information. You would think that they know the ideal air pressure, camber angle, and operating temperature for their tires. You would expect they have graphs that accurately depict the grip force with varying normal load, camber angle, air pressure, and tire temperature, and you would think that they know the spring rate per air pressure as well. At the mid to lower end of motorsports, they don't. The F1 guys do. LeMans probably yes. CART and NASCAR might. But at the level in which mere mortals compete, the tire companies don't do the sort of testing that the higher end series can. Most of the smaller companies (like Hoosier) don't own and cannot afford the type of equipment necessary to run these tests to gather this kind of data. And those that do guard that data very, very closely because if it reaches their competitors if gives valuable insight on how to beat them on the next tire design iteration.

The smaller companies don't "design" tires so much as "cook" them. They have a ton of experience and big "recipe books" that indicate how various types of rubbers and carcass construction are likely to behave, but often, they don't know how a tire will respond until it is built. That's why occasionally they'll be taken by surprise by an especially good or bad tire.

Which ultimately returns us to the requirement to test.

Time spent tire testing is seldom wasted.

The Goal

The Goal