King Canada KC-129C 5" x 6" Horizontal Bandsaw

A common task when making parts out of aluminum is the need to slice off chunks from bars of stock. You can do it with a Sawzall or a manual hacksaw, but that starts to become a lot of work as stock gets thicker. Powering a Sawzall through a 3" thick bar of 6061 - while you can do it - is a lot of work and tends to shake the hell out of the workbench.

The solution is a proper metal cutting horizontal bandsaw. Not only does it make a straighter cut, but it can be run semi-autonomously, so you can work on something else while the saw is doing the work.

I picked up a King Canada KC-129C 5" x 6" saw. This is very similar / identical to a number of other Chinese saws, like the Grizzly G0622.

It's clear that most of the cost of the saw went into the casting and motor, as the stand is just bolted-together sheet metal and the wheels are super crude. I'm not a huge fan of the plastic vice handwheel or the decent spring tension handle either. The saw has been cost-reduced up the yinyang to get the price down to where it is - better models cost twice as much and eat up twice the floor space too.

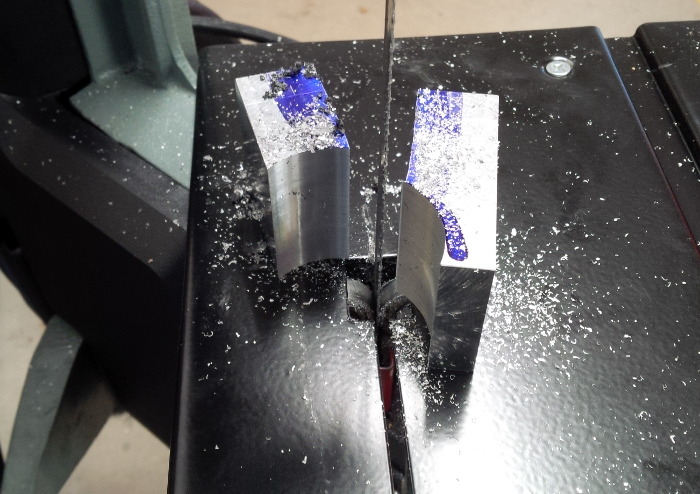

But with that said, the saw does do the job. King kept the quality up where it needed to:

Note that the stock blade has way too fine a tooth pitch for cutting big bar stock like that. It zips right through steel tubing, but it takes its time on thick stock. With a blade tooth pitch properly matched to the material thickness, it would cut much faster.

One nice feature of these smaller saws is that they can be raised fully upright and a table bolts on so the saw can be used as a vertical bandsaw. The table as provided is super flimsy and is just crying out for me to make a better version - but it does work.

When this blade wears out I'll get a good bimetal blade with the proper tooth pitch and watch performance jump way up. In the meantime though, this saw is still a huge productivity multiplier. It's faster than manual alternatives and much cleaner than my abrasive saw (for steel). If you have the floor space, getting one of the next models up, like one that has a swivel feature for cutting angles and/or a proper hydraulic down cylinder wouldn't be a bad idea, but I should have gotten one of these saws years ago.